Features:

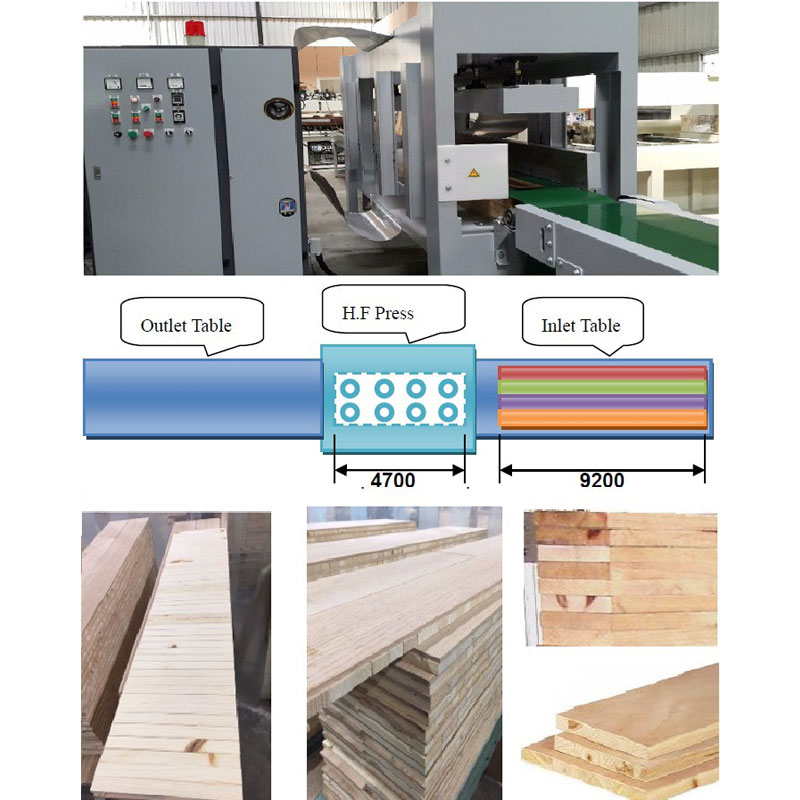

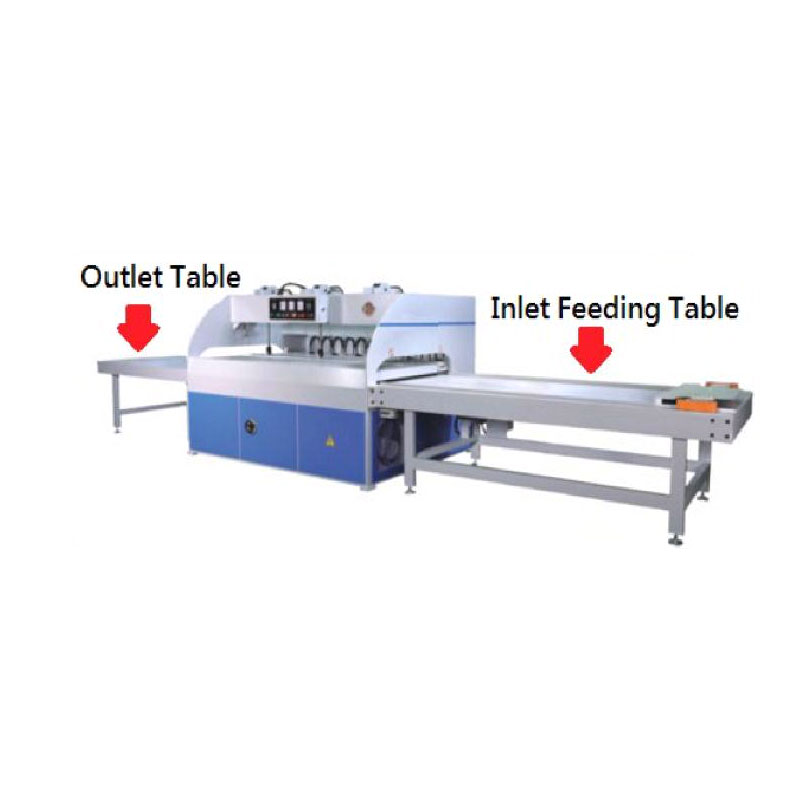

- Special design for mass production for engineer flooring, door stile, long panel, 2 to 3 minute to dry per cycle.

- Automatic infeed, outfeed cycle, mass production within 3 - 5 minutes is ready for output.

- Shortens manufacturing procedures – no need to pass through for the dovetailing or joining process.

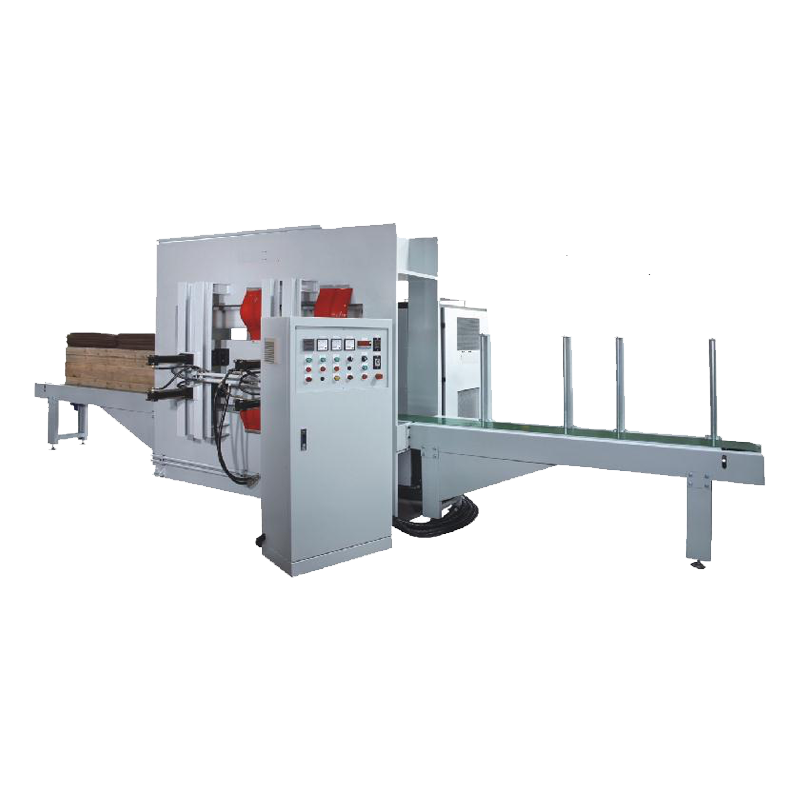

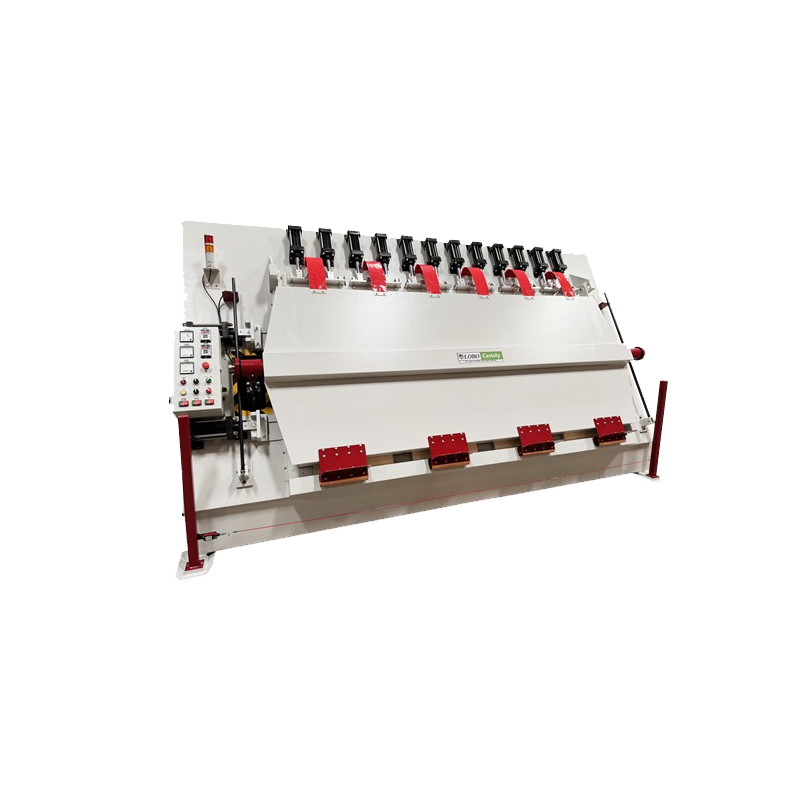

- Equipped with a massive upper plate that supplies powerful hydraulic pressure which presses each part of wood board to make even the most crooked pieces of wood flat.

- Due to the flatness it has made, it may not need to pass through double side planer processing.

- This substantially reduces wood loss.

- User friendly operations; it is equipped with side automatic inlet and outlet feeding table system for continuous and mass production.

- Top quality wood board is manufactured by way of glue cured and completely hardened glue joins with high frequency heating in the meantime.

- All processing steps are integrated into the HMI interface control panel for easy one-touch control on the screen.

- Utilizes high frequency, glue cured evenly from inner of the glue line of the wood.

Specification:

| Model No. | PT-HF1210-30FT |

| In Put Power | 100 KVA |

| Out Put Power | 60 KW |

| Max. Working Width | 10" |

| Max. Working Heigth | 12" |

| Maximum Working Length | 30ft |

| Pressure | 140 kg/cm2 |

| Hydraulic Pump | 15 HP |

| Press Cylinder (top) | 8 Pcs |

| Press Cylinder (Rear) | 46 Pcs |

| Driving Conveyor | 3 Units |

| In & Out Feed Belts Conveyor | 30 ft Length each |

| Machine Weight | 8000 LBS |

Related Products

-

12" x 118" Stile, Rail, Flooring High Frequency Press

PT-12118HF $98,900.00 -

20” x 24” High Frequency Press (each Unit)

PT-2024HF $25,900.00 -

3 Side Single Table Wood Board Joining 4'x8' High Frequency Press

PT-408S3HF-S $73,990.00 -

12"x 10" x 30ft Beam High Frequency Press

PT- HF1210-30FT $298,990.00 -

4" x 8" Automatic Wood Board Joining High Frequency Press

PT-48HF $73,990.00 -

13 KW High Frequency Genrater

PT-13HF-GN $26,900.00 -

3 Side Single Table Wood Board Joining 5'x10' High Frequency Press

PT-510S3HF-S $108,990.00 -

3 Side Double Table Wood Board Joining 4'x8' High Frequency Press

PT-408S3HF-D $146,990.00